- Home

- Newsletter

- July 2024 | Rebuild from A to Z: the welding process

July 2024 | Rebuild from A to Z: the welding process

01/07/2024 - 11:53

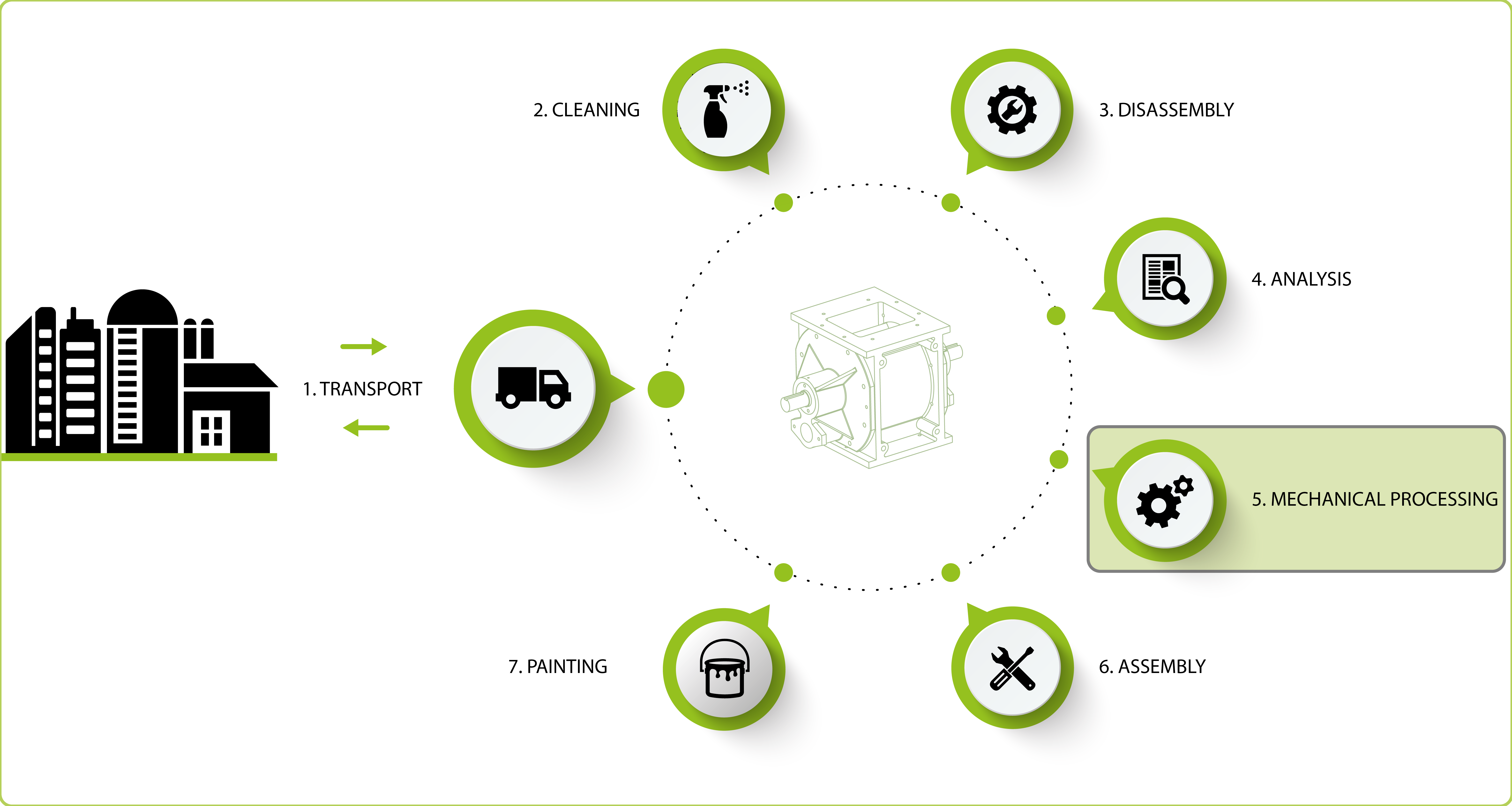

To refurbish a valve, four mechanical operations are required: milling, turning, boring, and welding. Each operation has its own specific challenges. Read more about the welding process in this newsletter.

Valves are made from (stainless) cast iron and commercial steel. Welding cast iron can be quite challenging due to several inherent properties of the material:

Cast Iron is Porous

The structure of cast iron is not closed. There are always microscopic openings in cast iron. These openings fill with residues of the traded product. These impurities are not visible to the naked eye and cannot be cleaned. They disrupt the welding process, making the penetration and strength of the weld uncertain. Avoid complications by using a double or slow weld.

Cast Iron is Brittle

Cast iron has low deformability (elasticity) and is therefore very sensitive to thermal stresses due to uneven expansion and contraction during welding. This can lead to deformation and cracking.

- To reduce cracking and thermal stresses, preheating the cast iron is often necessary to minimize the temperature difference between the base material and the weld material. Additionally, cast iron must be cooled slowly after welding to prevent stress cracks.

- Choosing the right welding wires and filler materials is crucial. By using elastic welding material, the base material is stretched as little as possible.

- By limiting the heat input in the welding process as much as possible (lower welding temperature), the temperature difference with the environment and thus the elasticity is reduced.

Welding cast iron is often a specialized task that requires careful preparation, the right materials and techniques, and often special equipment. Contact us for more information!