10/06/2024 - 11:17

A used valve tells a story

Due to the consistent and continuous handling of the product in combination with air, wear lines form on several parts of the valve (inlet opening, flange and stator wall, rotor blades, rotor shaft, outlet and blow openings). The wear lines reveal the weak points of the valve and also make it clear which components around the valve are not working properly:

Coatings

Many valves are provided with hard layers, or coatings, to increase their service life. Coatings make wear lines less visible or even completely invisible. Analysis becomes more difficult; the weak points remain hidden. Ideally, a standard valve is used without a hard layer and only after analyzing the first wear lines (and making proper adjustments) is it provided with a coating.

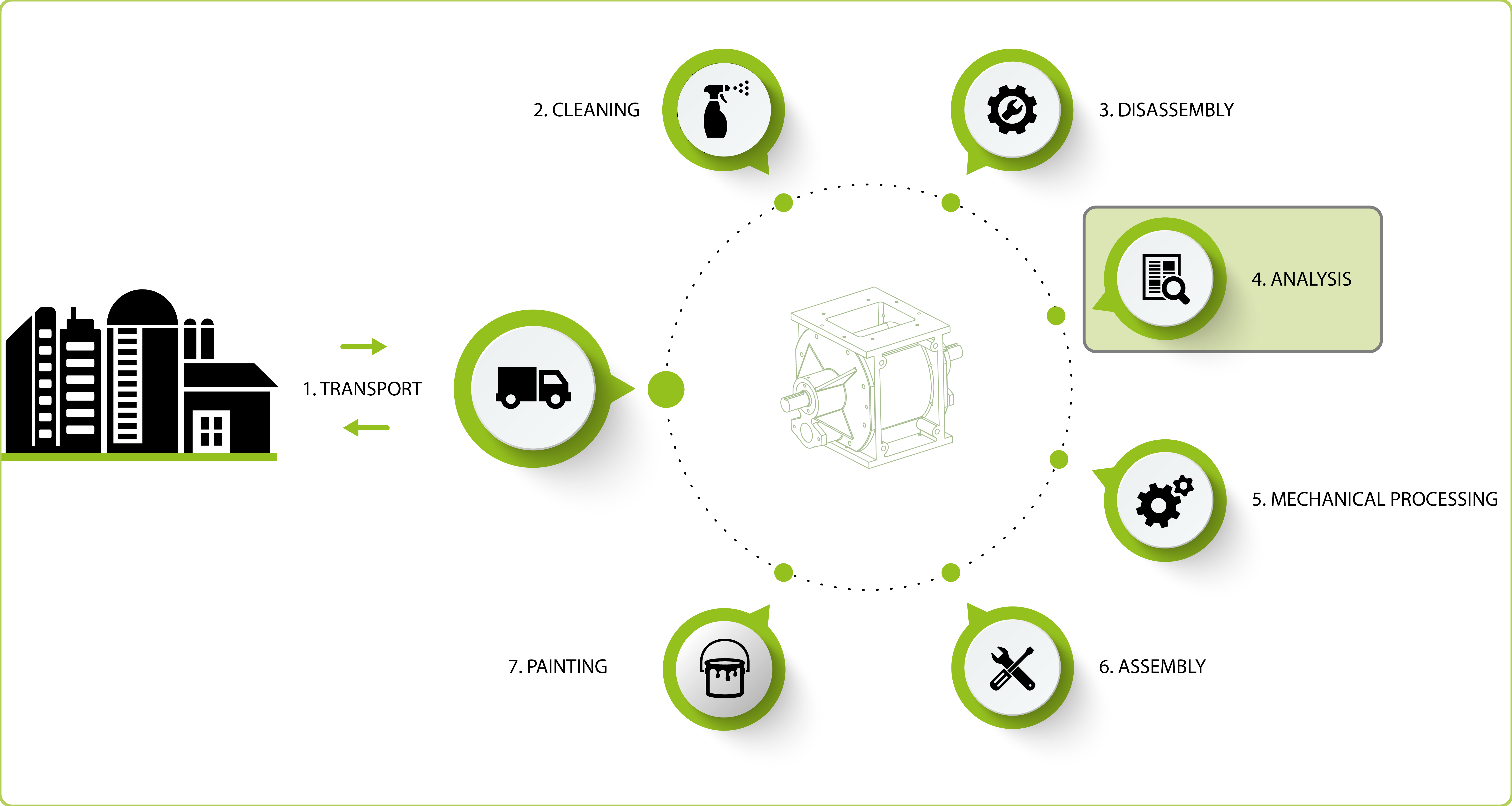

Analysis, where experience plays a role.

Analysis, where the biggest difference is made.

Analysis, the reason why rebuild is better than new.

This website uses cookies.