- Home

- Newsletter

- Material Selection for Rotary Valves

Material Selection for Rotary Valves

06/09/2024 - 08:54

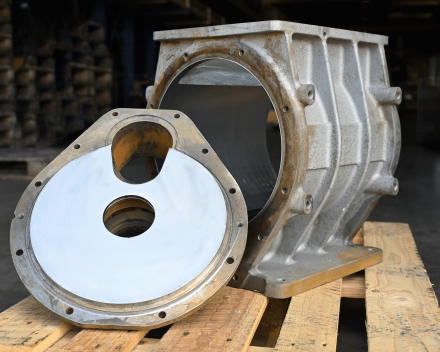

The construction of a rotary valve requires materials that are resistant to wear, corrosion, and the specific demands of the application. The choice of material depends on the type of bulk material being transported by the valve, the environment in which the valve is used, and the required durability.

- Cast Iron and Steel: The vast majority of rotary valves are made from a combination of cast iron (stator and flanges) and steel (rotor). Cast iron is strong, wear-resistant, and provides good structural stability. However, it is less resistant to corrosion compared to stainless steel, making it less suitable for use in corrosive environments. Additionally, cast iron is brittle, which makes it less suitable for the rotor that must withstand lateral impacts on the rotor blade.

- Stainless Steel: Stainless steel is resistant to corrosion, easy to clean, and suitable for hygienic applications. It is durable and resistant to chemical attack, making it suitable for use in corrosive environments. Nevertheless, it is recommended to use cast iron and steel if the application does not require corrosion resistance. Cast iron and steel are cheaper, stronger, and more wear-resistant.

- Alloy Wear-Resistant Steel: Alloy steel is used for rotary valves exposed to heavy mechanical stress and wear, such as in the processing of hard and abrasive materials.

In the construction of rotary valves, protective coatings are often applied to extend the life of the components. A commonly used method is applying a chrome layer, but other methods such as thermal spraying (coatings) are also used.

- A chrome layer is often applied to metal surfaces due to its excellent corrosion resistance and wear resistance, as well as its lower friction coefficient due to the smooth finish.

- Thermal spraying provides a more flexible and often thicker protective layer, used for restoring worn parts or for parts that need extra protection against extreme conditions. However, it comes with a higher cost compared to a chrome layer, although it offers greater wear and corrosion resistance and a lower friction coefficient.